Hand highlighting Work Safety words tag cloud on clear background

Hand highlighting Work Safety words tag cloud on clear background

Safety inspections are a key component in maintaining a safe work environment for all Aeronautical Center employees. These inspections play a crucial role in identifying hazards, assessing the effectiveness of safety measures, and ultimately ensuring the well-being of employees. Each year, the Office of Facility Management’s Facility Services Division (AMP-100) conducts a workplace inspection for all organizations at the Center.

In FY 2023, safety inspectors identified 260 safety findings during the annual workplace inspections. The total number of findings is an increase over the FY 2022 total of 161 but it is still well below the pre-global health crisis totals (424 findings in 2019). With the help of your awareness and proactiveness, the number of findings can decrease in FY 2024.

Here are the most cited findings in FY 2023 and ways you can help to avoid them in FY 2024.

- Material Handling and Storage – Leaning Materials

Pallets leaning against a table

Pallets leaning against a table

Plastic folding table leaning against a wall

Plastic folding table leaning against a wall

Power strip plugged into another power strip

Power strip plugged into another power strip

- Power Strips connected in Series (Daisy Chains)

Power strips and surge protectors should always be plugged directly into the wall outlet. Daisy chaining power strips can overload the circuits and cause fires. If your area does not have enough outlets, contact the AMP-300 trouble desk at (405) 954-3687 to have a technician come to see if more outlets can be installed.

- Cords Under Stress (Hanging Power Strips)

Power strip hanging from under desk

Power strip hanging from under desk

- Obstructed Egress

Toolbox items left scattered in walkway

Toolbox items left scattered in walkway

Paint supplies left in stairwell

Paint supplies left in stairwell

- Improper Material Storage

Heavy items stacked on top of less sturdy ones

Heavy items stacked on top of less sturdy ones

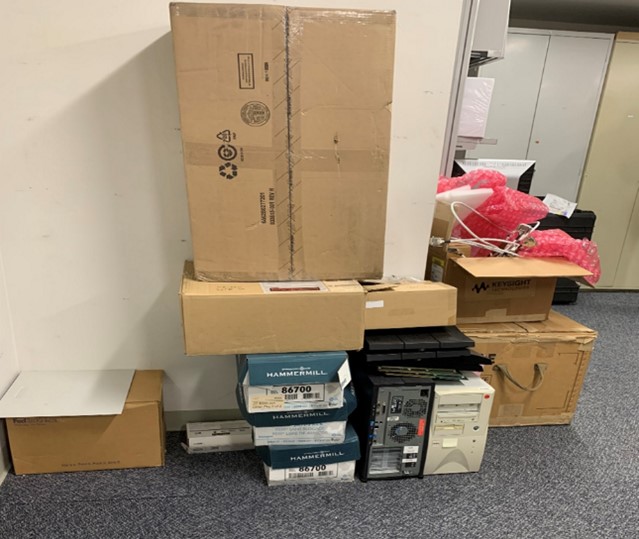

Multiple cardboard boxes stacked too high

Multiple cardboard boxes stacked too high

- Tripping hazards

Electrical cord crossing a hallway, causing a tripping hazard

Electrical cord crossing a hallway, causing a tripping hazard

Damaged flooring causing a tripping hazard

Damaged flooring causing a tripping hazard

The Annual Workplace Safety Inspections are an effective tool to ensure compliance with regulations and prevent accidents and injuries. Organizational management is also required to conduct quarterly inspections of their assigned areas. Together with your help, we can reduce the number of findings and ensure a safe, compliant, and productive work environment.

If you have any questions about the Workplace Inspection Program, contact Jason Palmeter at (405) 954-2337.